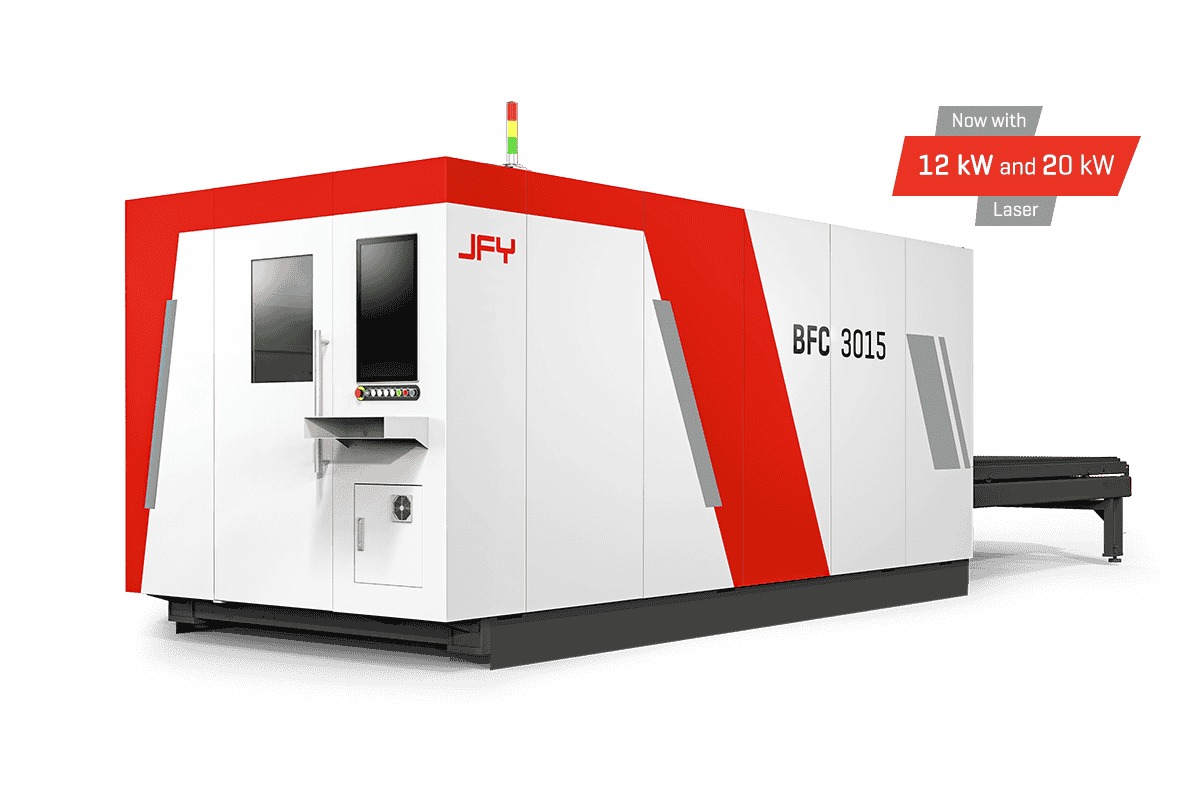

Cut time to market with JFY

A high-performance laser machine which opens a broad spectrum of cutting applications for various industries.

BEST price performance ratio

Reliable machine with higher cost effectiveness and professional manufacturing process.

High-End optics and cutting quality

Good optics and cutting quality with JFY fiber laser and Raytool cutting unit.

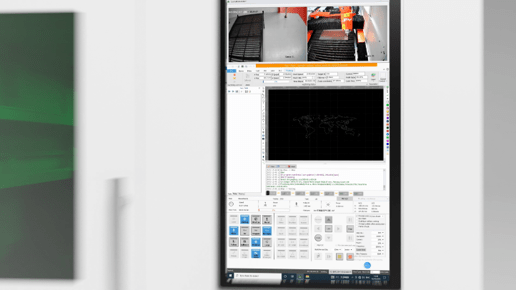

Easy to operate

Ergonomic design and operation with extra-large screen and online monitoring of cutting performance.

High machine safety

Fully enclosed machine with certified components to avoid laser radiation hazards.

Best in class Service

Dense and professional service network with local and on-site support.

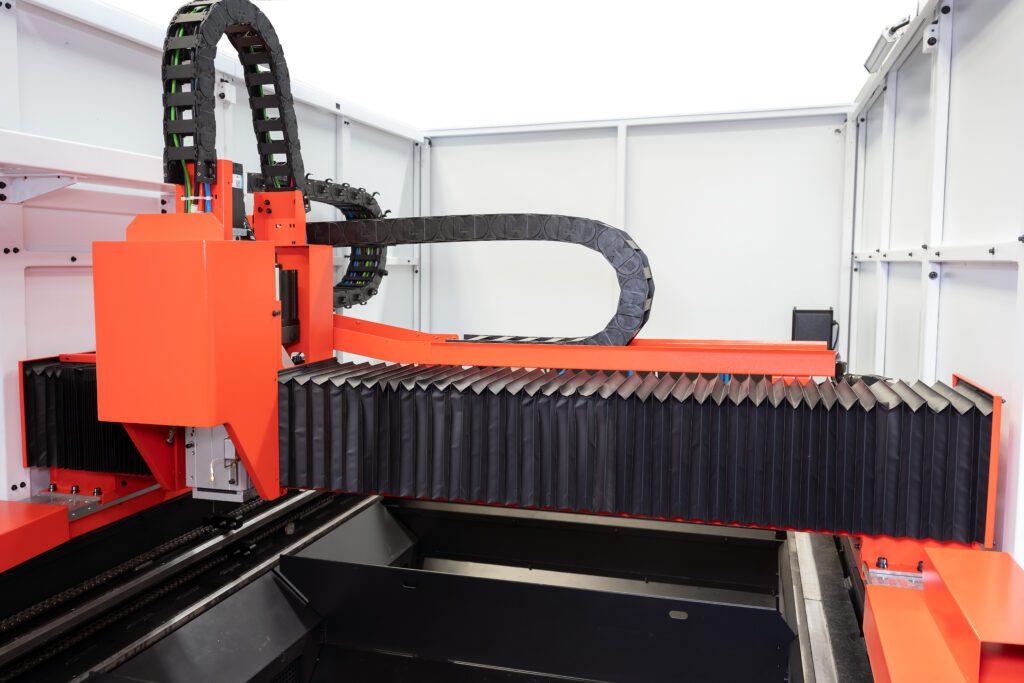

Features and Performance

Details

Reliable Optical Chain

- JFY New Generation Laser: High-power, compact single module fiber lasers with superior beam quality, certified to PL-d (ISO 13849-1) for outstanding safety performance—ideal for remote processing and high-frequency laser cutting.

- BOCHU Auto Focus Cutting Unit: Integrated sensors deliver real-time, closed-loop monitoring for rapid diagnostics and reduced downtime.

- Self-Service & Cost Efficiency: Anti-collision design allows customers to replace cutting heads themselves, lowering maintenance costs.

- Robust Cooling: A water cooling system covering 90% of the cutting head optical path ensures stable and efficient cutting performance.

Intuitive Control System

- Latest HMI from JFY and full-solution control system FSCUT, ensuring high performance, a user-friendly interface for easy setup and ergonomic operation.

- Support of various piercing functions (e.g. multiple stage piercing process, segmented and stepping patterns).

- Support of various cutting technologies (e.g. fly cut, frog-leap, kerf compensation and lead-in cutting functions).

- Support of various file formats to import designs directly into the system.

Excellent Stability and Accuracy

- Welded machine bed for superior torsion rigidity ensuring high part accuracy.

- Sectional welding technology according to latest manufacturing standards.

- Finite Element Analysis (FEA) ensures optimal structural integrity and performance.

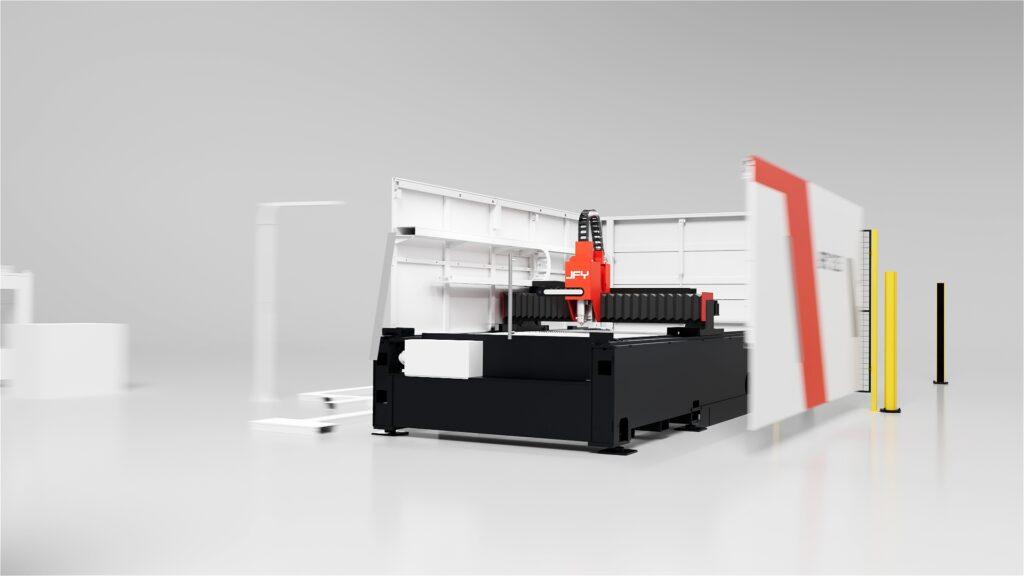

Automatic Exchange worktables

- Dual exchange worktables equipped with durable, high-performance movement units.

- Worktable exchange time of 10-16 seconds significantly increases work efficiency.

Carriage Beam

- Made of aviation-grade aluminum alloy.

- Lightweight design for ease of use.

- Well-balanced weight bearing capabilities.

- Outstanding dynamic performance.

Technical Data

| BFC 3015 | BFC 4020 | BFC 6020 | BFC 6025 | ||

|---|---|---|---|---|---|

| Maximum format size that can be processed | |||||

| X-axis | mm | 3050 | 4050 | 6050 | 6050 |

| Y-axis | mm | 1545 | 2050 | 2050 | 2550 |

| Z-axis | mm | 260 | 260 | 260 | 300 |

| Workpiece | |||||

| Max. weight (up to 6KW) | kg | 900 | 1600 | 2350 | 5900 |

| Max. speed | |||||

| Simultaneous | m/min | 140 | 140 | 140 | 140 |

| Max. acceleration | g | 1.7 | 1.7 | 1.7 | 1.7 |

| Max. positioning speed | m/min | 100 | 100 | 100 | 100 |

| Accuracy | |||||

| Positioning precision | mm/m | +/-0.03 | +/-0.03 | +/-0.03 | +/-0.03 |

| Repositioning precision | mm | +/-0.03 | +/-0.03 | +/-0.03 | +/-0.03 |

| Cutting precision | mm/m | +/-0.1 | +/-0.1 | +/-0.1 | +/-0.1 |

| Machine performance | |||||

| Control system | FSCUT | FSCUT | FSCUT | FSCUT | |

| Pallet changer change time | sec | 10 | 13 | 16 | 25 |

| Machine weight | kg | 8000 | 10000 | 13000 | 14000 |

Laser Data

| JFY 3 KW | JFY 6KW | JFY 12KW | JFY 20W | ||

|---|---|---|---|---|---|

| Max. power | W | 3000 | 6000 | 12000 | 20000 |

| Max. sheet thickness | |||||

| Mild steel | mm | 22 | 25 | 40 | 50 |

| Stainless steel | mm | 16 | 25 | 40 | 50 |

| Aluminum | mm | 12 | 20 | 40 | 50 |

| Brass | mm | 10 | 20 | 20 | 20 |

| Copper | - | - | - | - | |