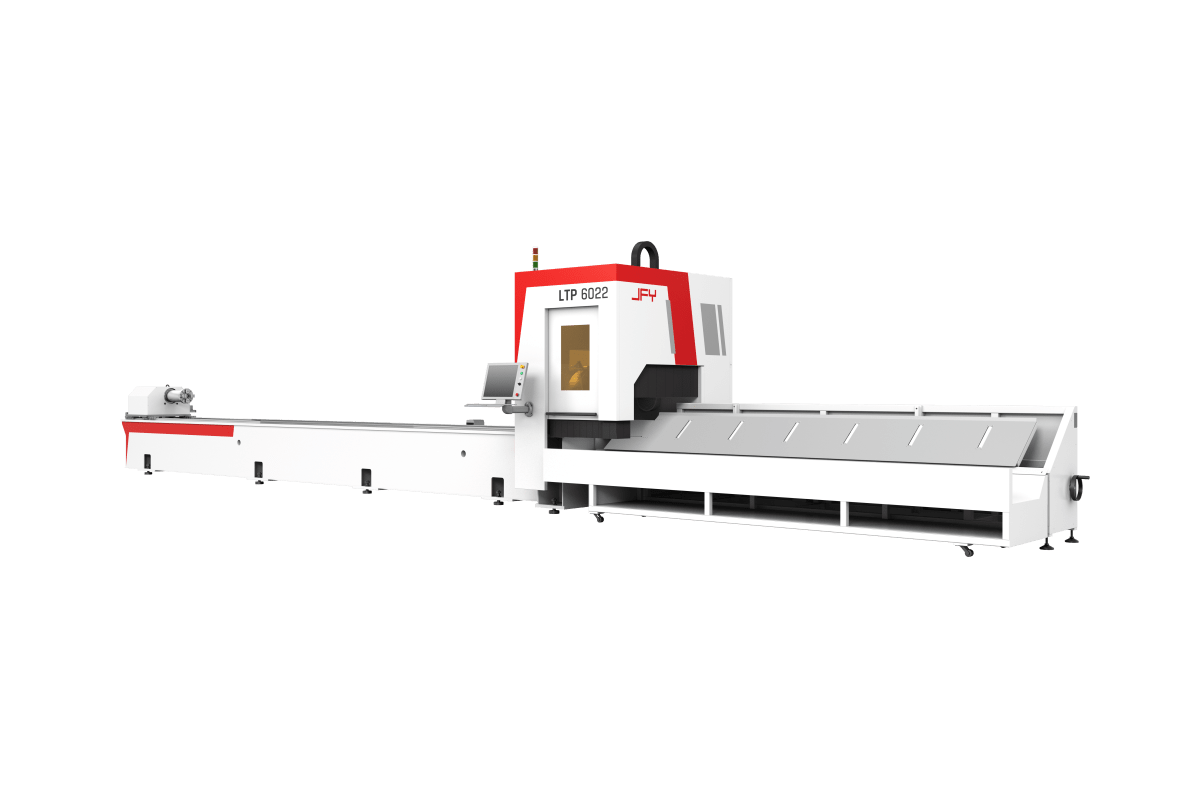

Cut time to market with JFY

The LTP series delivers high-precision tube processing with superior productivity and ease of use. It features built-in protective glasses for enhanced cutting head durability and precision, dual cooling circuits for stability, and auto-focus for efficient cutting. The FSCUT5000 with EtherCAT BUS system offers flexible, real-time control, while JFY’s advanced fiber laser technology ensures stable, high-frequency cutting with excellent seam quality and low maintenance.

High-End cutting quality

Professional cutting system and JFY auto-focus cutting head and fiber laser ensure the reliability of machine operation and high cutting quality of various tubes.

Easy to use and program

The ergonomic design of the CNC system and the large 19-inch screen support 3D import, allowing real-time dynamic simulation and easy operation.

Efficient production

Automatic loading system enables high-volume and efficient production.

Accurate processing

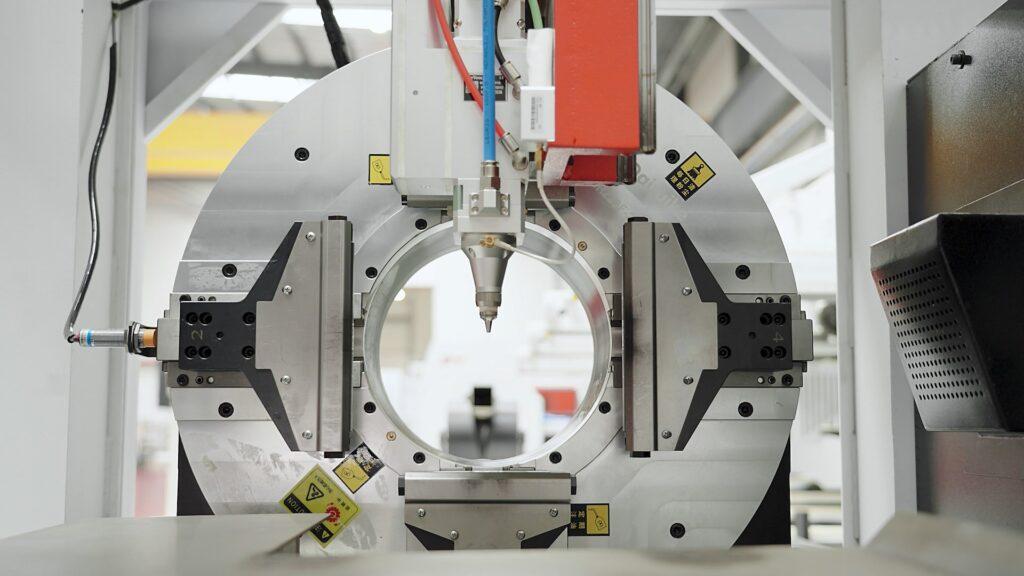

The chuck ensures precise and accurate machine processing through reliable clamping of tubes enabled by high precision gears, rack and pinion.

Best in class Service

Dense and professional service network with local and on-site support.

Features and Performance

Details

Reliable Optical Chain

- RayTools auto focus cutting unit with built-in protective glasses for increased durability and cutting precision.

- Enhanced dual cooling circuits ensure better cutting stability and performance.

- Auto focus function reduces manual intervention, improving power penetration and cutting efficiency.

- JFY’s new fiber laser generation supports stable, high-frequency cutting with superior seam quality and material surface cleanliness.

- High beam quality and power efficiency for optimal cutting performance.

- Single module laser design reduces maintenance effort and ensures long-term reliability.

Tube Supporting Unit and Machine frame

- Feeler wheels adjust to the tube’s diameter and rotate for proper fit.

- Positioning pins are secured for stability.

- Tube loading can be manual or semi-automatic.

- Feeding chuck moves to the correct position for tube clamping and feeding.

- Machine bed welded with optimized interlocking structure for excellent rigidity and stability.

- Sectional welding technology ensures long-term deformation-free durability.

- Superior anti-vibration capability thanks to optimized machine dynamics.

Easy to use CNC Control

- 19’’ large screen with fast toolbar for easy size and location adjustments.

- EtherCAT bus system FRIENDESS FSCUT 5000 designed for fiber laser tube cutting, offering faster and more stable performance.

- Supports 3D drawing input (IGS, SAT, JHB) with easy editing for angle iron, channel beam, and H steel.

- Real-time compensation for tube center deviation and dynamic simulation for easy program entry.

- Cutting unit avoidance and part correction features for enhanced precision.

Technical Data

| LTP 6022 | LTP 6032 | LTP 9032 | ||

|---|---|---|---|---|

| Maximum format size that can be processed | ||||

| X-axis | mm | 330 | 330 | 330 |

| Y-axis | mm | 7000 | 7000 | 10000 |

| Z-axis | mm | 280 | 280 | 280 |

| Workpiece | ||||

| Tube size round | mm | 20-220 | 20-320 | 40-320 |

| Tube size square | mm | 20-150 | 20-220 | 40-320 |

| Max. weight of tube | kg | 250 | 400 | 400 |

| Max. speed | ||||

| Max. acceleration | g | 1.2 | 0.8 | 0.8 |

| Max. positioning speed | m/min | 100 | 80 | 80 |

| Accuracy | ||||

| Positioning precision | mm/m | +/-0.03 | +/-0.03 | +/-0.03 |

| Positioning precision | mm | +/-0.02 | +/-0.02 | +/-0.02 |

| Machine performance | ||||

| Control system | FSCUT | FSCUT | FSCUT | |

| Rotation of B1, B2 axis | degree | 360 | 360 | 360 |

| Max rotation of chuck | r/min | 100 | 60 | 60 |

| Machine weight | kg | 7000 | 8500 | 19200 |

Laser Data

| JFY 3KW | ||

|---|---|---|

| Max. power | W | 3000 |

| Cutting unit | Raytiool | |

| Wavelength | nm | 1080 +/- 5 |

| Terminator Type | QBH | |

| Output Fiber | um | 50 |

| Max. sheet thickness | ||

| Mild steel | mm | 8 |

| Stainless steel | mm | 4 |

| Aluminum | mm | 4 |

| Copper | - | |

| Brass | mm | 10 |

| Power consumption | ||

| Average power consumption during production | kw | 32 |