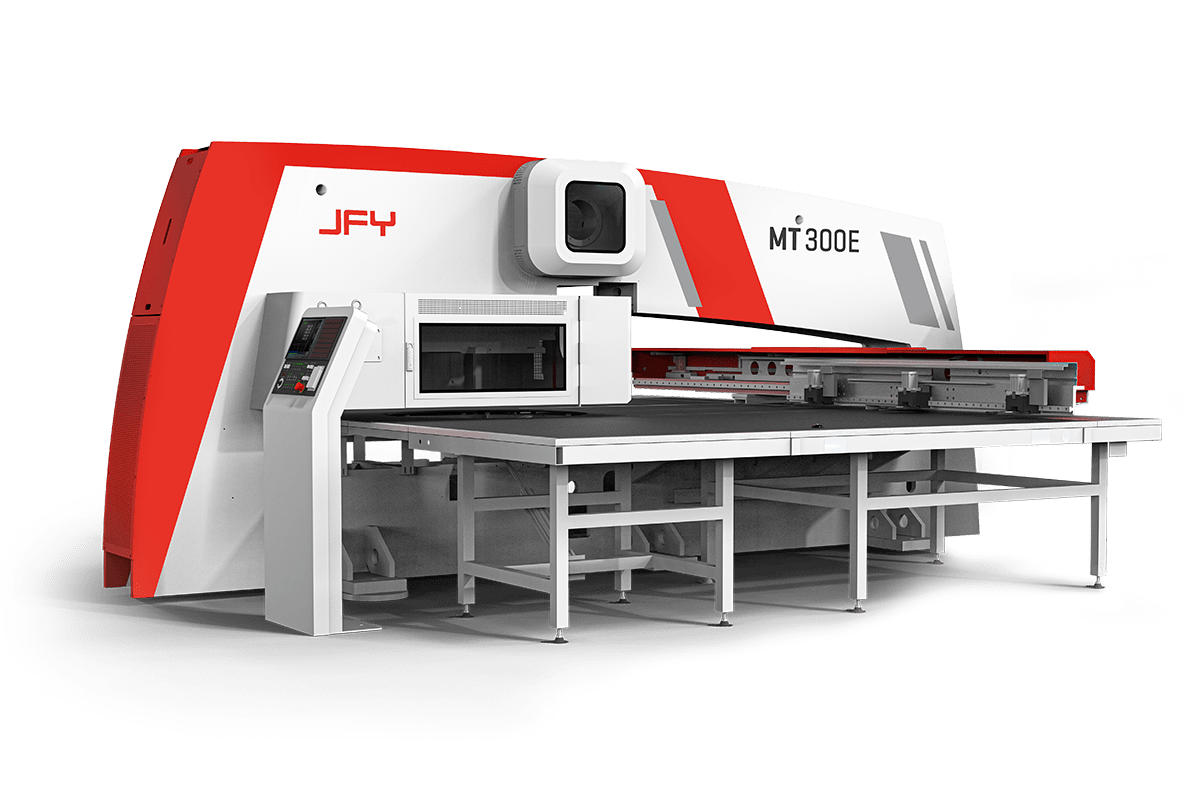

Punch efficiency with JFY

The MT Series offers maximum performance at low investment costs. With over 20% market share in China, the MT300E is the leader in its class. Flexible for different formats, efficient thanks to customised automation solutions, and user-friendly thanks to the stable FANUC CNC system – for reliable and versatile production.

Easy to Use

Stable operation thanks to the special FANUC CNC system. The professional programming software can significantly improve the operation reliability.

Efficient production

The APE/ APC loading and unloading automation can be customized according to the specific requirements for efficient production.

Flexible production for multiple formats

Available in small, medium and large formats, which can be applied to punch versatile sizes of sheets.

Best in class Service

Dense and professional service network with local and on-site support.

Features and Performance

Details

Reliable and Robust Punching Solution

- Direct drive torque servo motor with high overload capacity ensures low energy consumption, high transmission efficiency, and reliable performance.

- Adjustable punch force adapts to sheet thickness and speed for maximum punching quality.

- Advanced floating clamp technology for smooth feeding and automatic clamp protection to prevent tool and clamp damage.

- Standard turret with 32 stations offers ample capacity for a wide range of punching needs, including holes and shapes.

- Convenient maintenance and consistent performance for long-term operation.

Efficient and User-Friendly Programming

- CNCKAD software converts CAD files into optimized NC code, automating tool selection and minimizing machine runtime.

- Simplified G-code programming for quick and easy operation, supported by the FANUC 0i-PF CNC system for easy and fast operation.

- Features include automatic punching, adaptable microjoints, predefined shapes, and efficient sheet trimming for maximum material utilization.

- Advanced functionality such as customizable turret setup, sheet repositioning, auto indexing, and clamp avoidance for seamless processing.

Technical Data

| Item | Unit | Parameter |

|---|---|---|

| Nominal force | kn | 400 |

| Main drive | / | Servo Motor |

| Bending accuracy | mm | |

| Max. bending angle | mm | 90 |

| Working speed | mm/s | 0-13 (adjustable) |

| Quick return speed | mm/s | 50 |

| Max. working stroke | mm | 200 |

| Back gauge stroke | mm | 2000 |

| Total power | kw | 7 |

| Max. vertical bending size | mm | 200 * 15 (W * T) |

| U-shaped bending width (optional) | mm | 60 |

| Max. flat bending size (optional) | mm | 125 * 10(W*T) |

| Dimensions (L * W * H) | mm | 4300 * 2200 * 1690 |