Bend your limits with JFY

Efficient bending, environmentally friendly and low-maintenance – with the direct-drive servo motor, the TPE8 series increases processing efficiency by more than 1.5 times, reduces energy costs by over 70% and delivers precise bending results at the same time. Compact in design, flexible in installation and easy to maintain – for maximum productivity and sustainability.

Efficient bending

Direct-drive servo motor increases processing efficiency by more than 1.5 times compared to traditional hydraulic press brakes.

Carefree maintenance and service

Compact machine body as well as simple drive principle enable a flexible installation and cost-effective maintenance.

Green and energy efficient

Direct drive servo motor enables you to not only save more than 70% of energy costs but also contributes to environmental protection.

Stable and precise

Bending speed can be adjusted for different workpieces. By using optimal algorithms and motion trajectory control the bending precision is enhanced.

Best in class Service

Dense and professional service network with local and on-site support.

Features and Performance

Details

Electric Drive System

- Direct-drive servo motor offers a high response speed, enabling processing efficiency over 1.5 times higher than that of a traditional hydraulic press brake.

- Compared to traditional electric press brakes, the direct-drive eliminates the need for belts. This results in higher precision.

Easy to use CNC Control

- With elegant and uncomplicated design, the machine offers an intuitively user-friendly experience.

- By using optimal control algorithms and motion path control, it ensures highly precise bending accuracy.

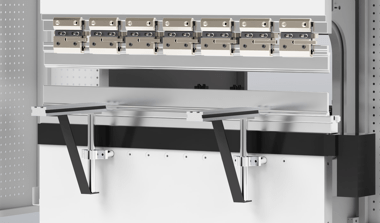

Backgauge System

- Experience swift and precise backgauge positioning, delivering high-speed performance and accuracy.

- Enjoy the flexibility of expanding from the standard 2-axis configuration to a 4-axis setup.

- The utilization of a robust box-type structure ensures long-term stability and reliable operation.

Technical Data

| Main Specification | Unit | 40 T | 50 T | |||

|---|---|---|---|---|---|---|

| Model | TPE8 040/1300 | TPE8 050/1500 | TPE8 050/2050 | |||

| Manimum bending force | kn | 400 | 500 | 500 | ||

| Bending length | mm | 1300 | 1500 | 2050 | ||

| Column interval | mm | 1100 | 1200 | 1600 | ||

| Depth of throat opening | mm | 300 | 300 | 300 | ||

| Slider stroke | mm | 165 | 165 | 165 | ||

| Closed height | mm | 420 | 520 | 520 | ||

| Slider speed without load | mm/s | 160 | 160 | 160 | ||

| Slider working speed | mm/s | 30 | 30 | 30 | ||

| Slider return speed | mm/s | 160 | 160 | 160 | ||

| Main motor power | kw | 2x15 | 2x15 | 2x15 | ||

| CNC system | ||||||

| Rear blocking | X Axis | Repeat | mm | +/-0.01 | +/-0.01 | +/-0.01 |

| Travel | mm | 500 | 500 | 500 | ||

| Speed | mm/s | 400 | 400 | 400 | ||

| Motor power | kw | 1 | 1 | 1 | ||

| R Axis | Repeat | mm | +/-0.01 | +/-0.01 | +/-0.01 | |

| Travel | mm | 200 | 200 | 200 | ||

| Speed | mm/s | 200 | 200 | 200 | ||

| Motor power | kw | 1 | 1 | 1 | ||

| Z1, Z2, Axis | Repeat | mm | - | +/-0.1 | +/-0.1 | |

| Travel | mm | - | 350 | 850 | ||

| Speed | mm/s | - | 300 | 300 | ||

| Motor power | kw | - | 0.75 | 0.75 | ||

| External dimensions | Length | mm | 2100 | 2200 | 2900 | |

| Width | mm | 1580 | 1650 | 1650 | ||

| Height | mm | 2900 | 2900 | 2900 | ||

| Main drive type | Screw drive | |||||

| Compensation mode | None | Mechanical compensation | ||||