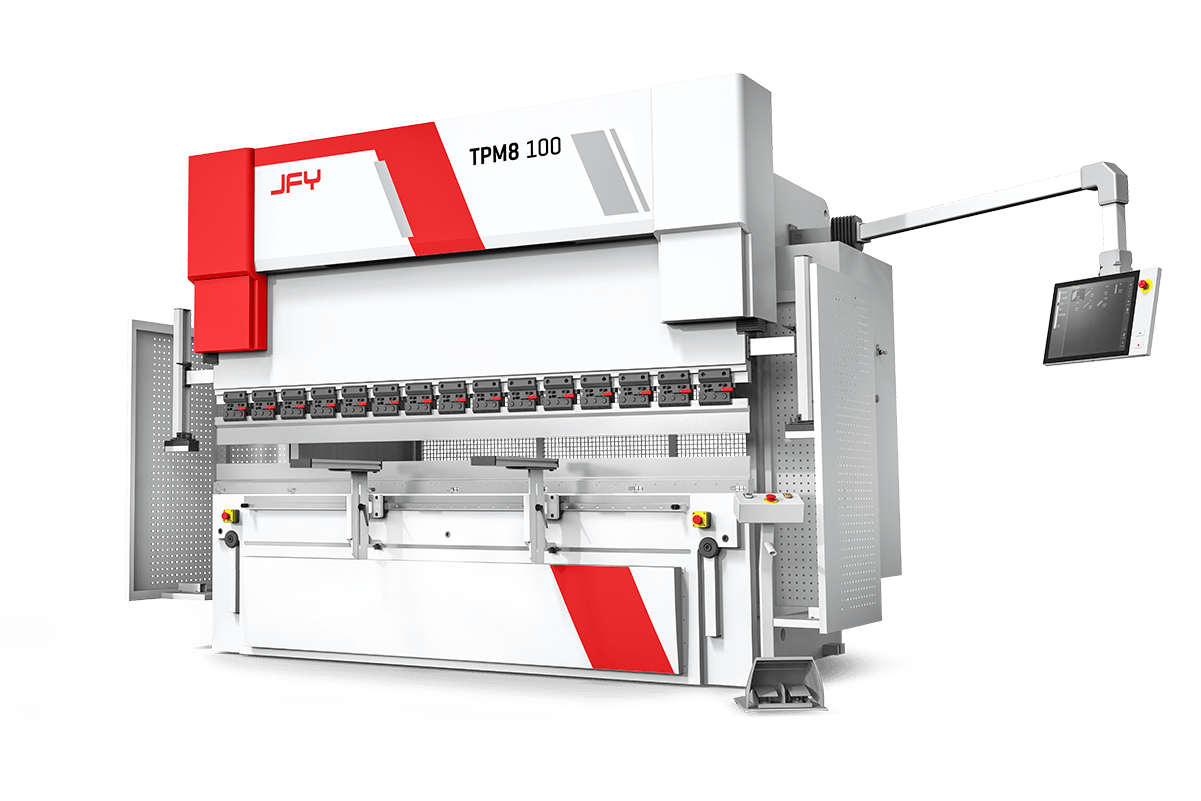

Bend your limits with JFY

BEST price performance ratio

The TPM achieves exceptional productivity due to its rigid frame structure, durable hydraulic crowning, and an automatic compensation system that ensures workpiece linearity and precise bending angles. Additionally, the user-friendly TJS-90 control accelerates job preparation.

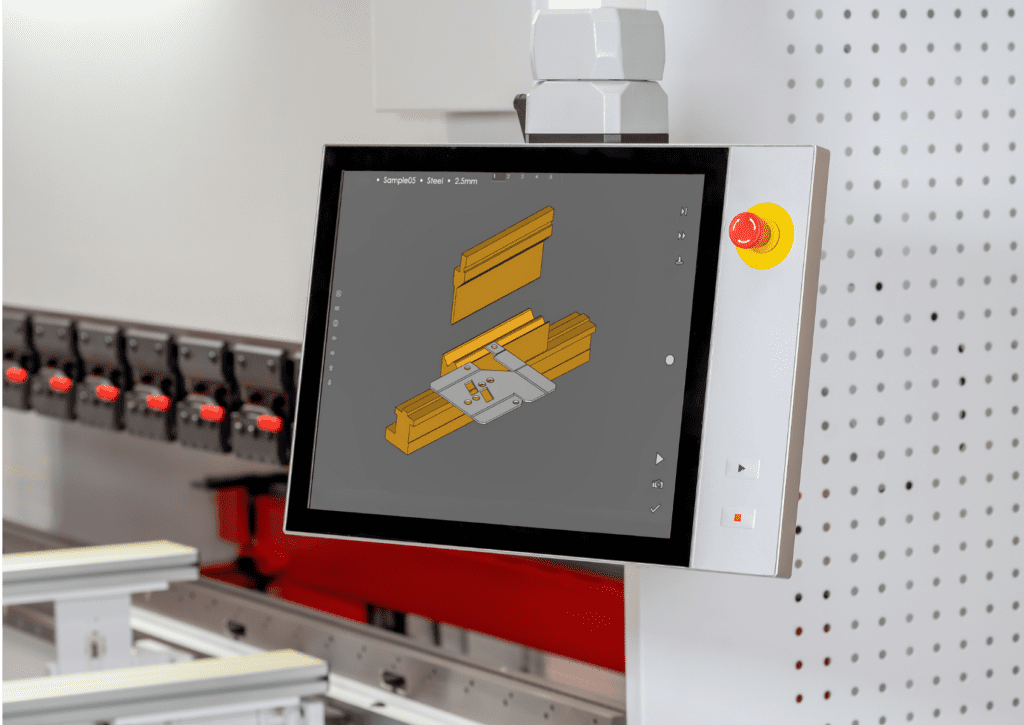

Easy to operate

The TJS-90T system, equipped with a 19-inch touch screen, automates job preparation and provides a 3D visualization of potential collisions during the bending process.

Bulletproof machine safety

Machine is equipped with light barrier and redundant safety circuit detection to ensure operator’s safety.

Best in class Service

Dense and professional service network with local and on-site support.

Tooling

Comprehensive tooling solutions and attractive starter packages for beginners and pros.

Watch our TPM 8 in action!

Experience firsthand how this innovative machine combines flexibility, safety, and efficiency to elevate your bending operations. Don’t miss the opportunity to see how the TPM8 can transform your production process.

Features and Performance

Details

Efficient Servo Motor

- Servo motor cuts energy use by about 40% compared to an AC motor.

- Ram efficiency is 17-21% higher than the previous model.

- Significantly reduces oil temperature for better performance and longevity.

Intuitive TJS Control

- Windows 10 Enterprise with 19″ LCD touch screen, 1280 x 1024 resolution, and multi-touch support.

- Digital/2D graphic contour programming technology with 3D view, automatic bending process preparation, and bending simulation.

- Supports CAD file import (DXF), 3D file import (IGS), flexible automatic calculation of bending processes, and collision detection for workpiece, mold and fuselage.

Integrated Hydraulic System

- Electro-hydraulic system controls dual cylinders for high, synchronized accuracy in bending and repositioning.

- Integrated hydraulic control system prevents oil leakage, and enhances machine stability.

Hydraulic Crowning System

- Hydraulic auto crowning system eliminates the impact of sliding block deformation on bending quality.

- CNC system automatically adjusts the crowning value for precise and convenient operation.

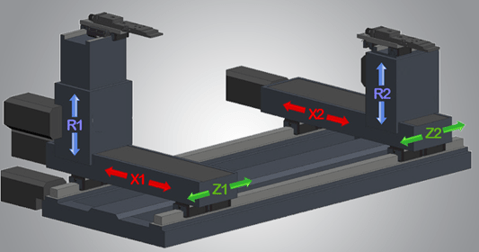

Flexible Backgauge System

- High speed and high positioning accuracy.

- Multi-functional backgauge extends from a standard single-axis up to a 4-axis configuration.

Technical Data

| Main Specification | Unit | 60T | 100T | 150T | 225T | 320T |

|---|---|---|---|---|---|---|

| Model | 60/2050 | 100/3100 | 150/3100 | 225/3100 | 320/4100 | |

| Max. Bending Force | kn | 600 | 1000 | 1500 | 2250 | 3200 |

| Max. Bending Length | mm | 2050 | 3100 | 3100 | 3100 | 4100 |

| Column Distance | mm | 1600 | 2700 | 24700 | 2700 | 3700 |

| Throat Depth | mm | 350 | 410 | 410 | 410 | 410 |

| Ram Stroke | mm | 215 | 215 | 215 | 215 | 315 |

| Closed Height | mm | 480 | 480 | 480 | 480 | 580 |

| Approaching Speed | mm/s | 180 | 220 | 180 | 160 | 120 |

| Working Speed | mm/s | 10 | 10 | 10 | 10 | 9 |

| Return Speed | mm/s | 180 | 210 | 180 | 160 | 110 |

| Main Motor Power | kw | 8.5 | 12.4 | 17.8 | 21.4 | 25.2 |

| Oil Tank Capacity | l | 250 | 400 | 400 | 400 | 550 |

| Machine Weight | kg | 5320 | 8350 | 9950 | 13550 | 22500 |