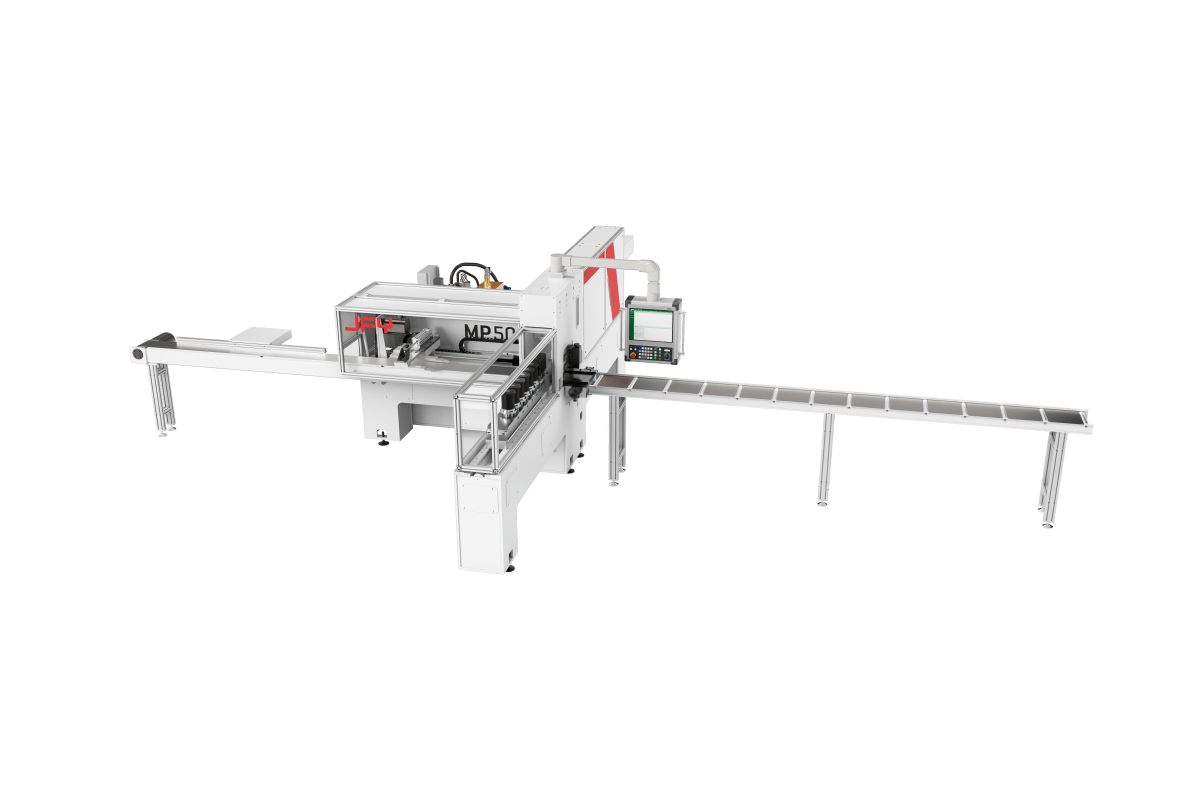

Punch efficiency with JFY

The MP50 Series is used for the professional processing of busbars with functions such as punching, cutting and embossing. The innovative T-shaped design combines compact aesthetics with high stability. With 7+1+1 and 8+1 tool stations, it offers maximum flexibility and efficiency. The hydraulic drive ensures quiet, stable operation and continuous production.

Exceptional bending accuracy

State-of-the-art servo motor drive ensures precise control over the bending angle. Paired with an advanced electronic angle measurement system, it delivers exact angle compensation, guaranteeing superior accuracy and reliability in every bend.

Multifunctional integration

Supports configurations of 7+1+1 and 8+1 tool stations, which allows not only punching operations but also cutting, embossing, and other functions, providing high processing efficiency and flexibility.

High stability

Combines a high frequency, low-noise, and low-oil-temperature hydraulic workstation with mechanical transmission, ensuring high compatibility and continuous production.

Best in class Service

Dense and professional service network with local and on-site support.

Features and Performance

Technical Data

| Item | Unit | Parameter |

|---|---|---|

| Nominal Force | kn | 500 |

| Max.positioning speed (x/y axis) | m/min | 80 |

| Max. feeding stroke (x axis) | mm | 1000 |

| Max. tooling movement stroke (y axis) | mm | 1350 |

| Max. punching tooling movement stroke (V axis) | mm | 350 |

| Max. punching frequency | hpm | 120 |

| Tooling stations | piece | 7+1+1 (optional 8+1) |

| Controlled Axes | number | 3 |

| Pitching accuracy | mm | +/- (0.1 + (L/4000)) mm (Within +/-0.2 mm for L<400) |

| Max. plate thickness for punching | mm | 15 mm for copper, 10 mm for steel |

| Workpeiece size (L * W) | mm | 6000 * 200 |

| Max punching disameter | mm | 35mm for copper bars |

| Max cylinder stroke | mm | 60 |

| Max. cutting width | mm | 200 mm for copper bars |

| Max. embossing area | mm2 | 160 * 80 |

| Max. hydraulic pressure | bar | 270 |

| Air pressure | Mpa | 0.6 |

| Dimensions (L * W * H) | mm | 8500 * 4865 * 1800 |